Environment

Buzzi Unicem demonstrates its firm commitment to reducing the environmental impacts associated with its business operations by continuously improving production processes in its plants. From this standpoint, the most important environmental aspects assessed include the use of recycled materials, water consumption, percentage of water recycled during the production cycle, consumption of thermal energy, caloric substitution rate, consumption of electrical energy, waste production and the percentage of recycled waste. Due to its importance, atmospheric emissions are dealt with in a special section.

Consumption of materials

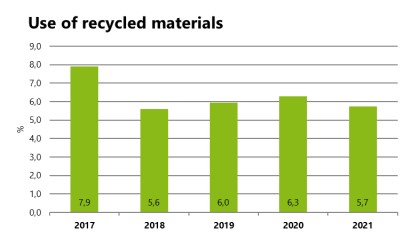

In certain circumstances, some natural raw materials can be replaced by waste materials deriving from other industrial processes that, in most cases, would otherwise be disposed of in landfills. In some situations, the use of these materials also helps improve the company’s emissions profile.

Replacing these natural raw materials thus accomplishes the twofold advantage of conserving natural resources and reducing the amount of material going to the landfill.

National Green Public Procurement (GPP) policies, such as the adoption of the Minimum Environmental Criteria (CAM) within the construction industry, establish award criteria for products with a high content of “recycled” material, in line with the principles of the circular economy. Please see the Environmental Product Section for further information.

Replacement has changed over the last five years as a direct result of the availability of replacement materials on the market and of the difficulties in obtaining the necessary permits.

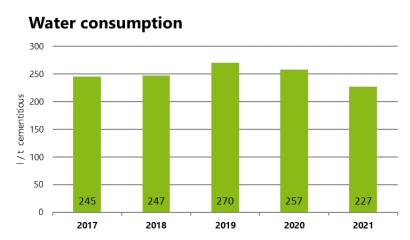

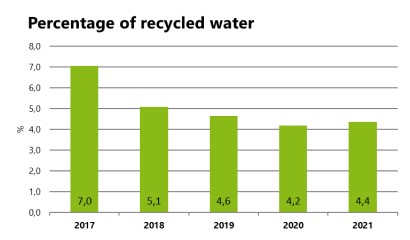

Water consumption

Water consumption during the cement production cycle is mainly used for conditioning the gases exiting the kilns, reducing the temperature during the cement grinding process, cooling engine parts, and reducing the dispersal of dust within the plants.

By regularly monitoring of consumption and usage levels, we can optimize water consumption and facilitate the recycling of rainwater.

While water consumption has been irregular, a good percentage of the consumption was derived from rainwater, which is also closely linked to rainfall.

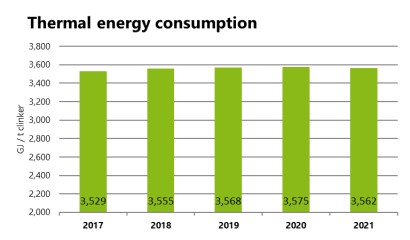

Energy consumption

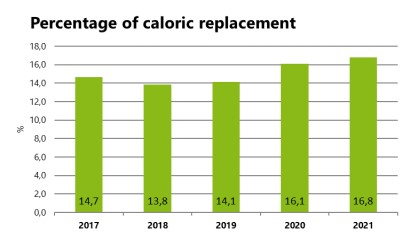

The cement production cycle, and the production of clinker in particular, requires a high level of thermal energy. The kilns must reach internal temperatures of around 1450°C through a combustion process to obtain the chemical/physical characteristics of the product. Buzzi Unicem seeks to minimize the use of fossil fuels in the combustion process by replacing them with alternative fuels, particularly those derived from the treatment of unsorted municipal waste, much of which has a good biomass content and thus lower CO2 emissions. The European Union recognizes the use of alternative fuels as a Best Available Technique (BAT) within the cement industry and is one of the pillars of the circular economy. The use of alternative fuels offers two main advantages: it reduces CO2 emissions depending upon the biomass content, and minimizes waste disposal in landfills.

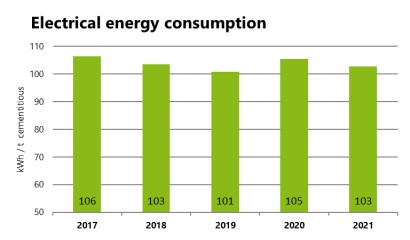

Reducing our consumption of electrical energy and obtaining our supply from renewable energy sources are two specific goals of Buzzi Unicem. Approximately 10% of our total energy use is required for cement production, and we can ensure the reduction of this impact by conducting special Energy Audits and continuing to invest in initiatives to increase the efficiency of the entire production process.

Specific thermal and electrical consumption have been more or less constant in recent years, varying by a few percentage points each year. In contrast, caloric substitution has grown due to the increased use of alternative fuels.

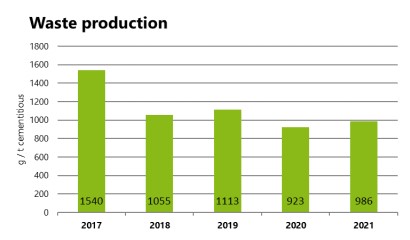

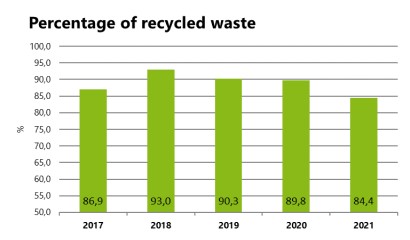

Waste production

Our waste production derives mainly from our routine maintenance and extraordinary maintenance operations, laboratory activities and demolition projects. Therefore the amount of waste may vary significantly from year to year. Buzzi Unicem is committed to further sorting and separating the waste we produce, as shown in the graphs below.